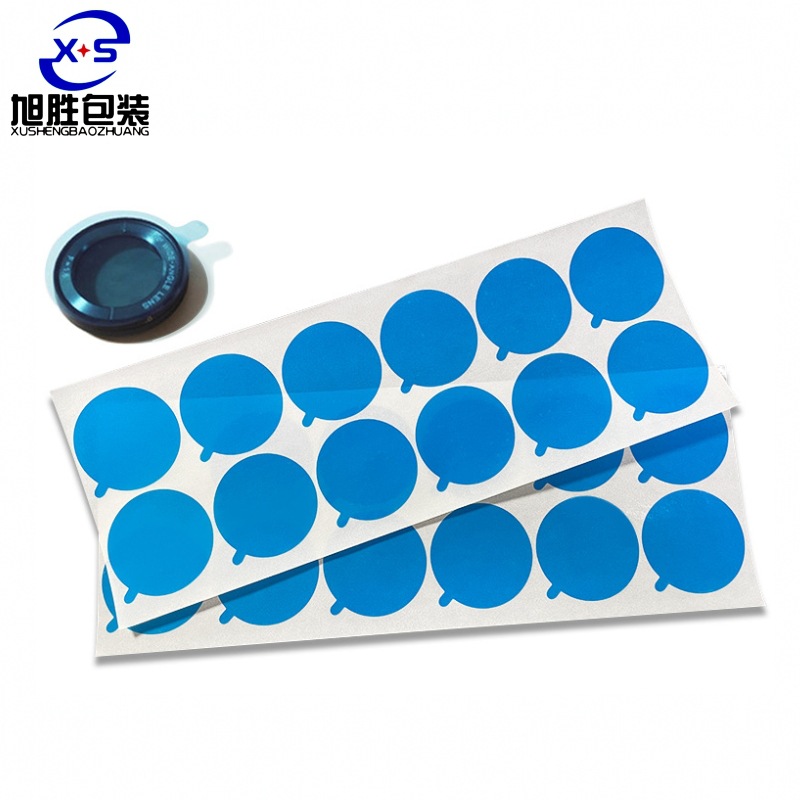

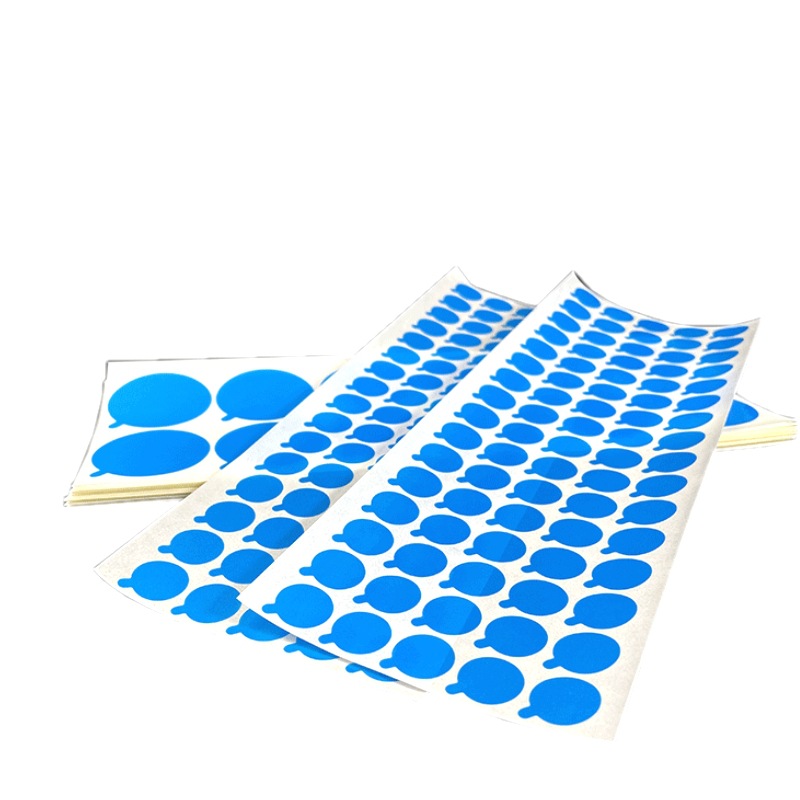

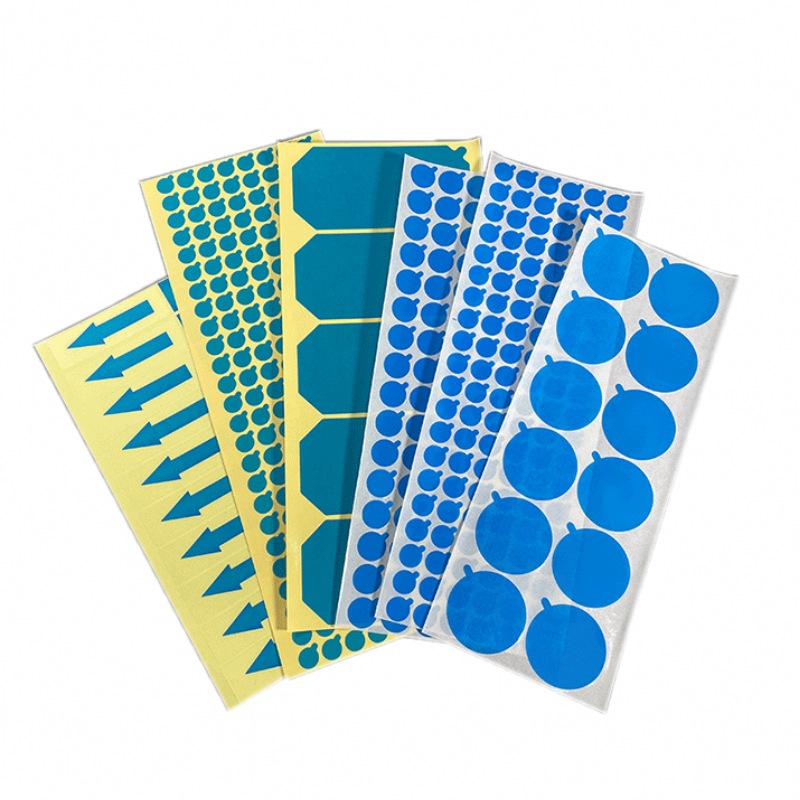

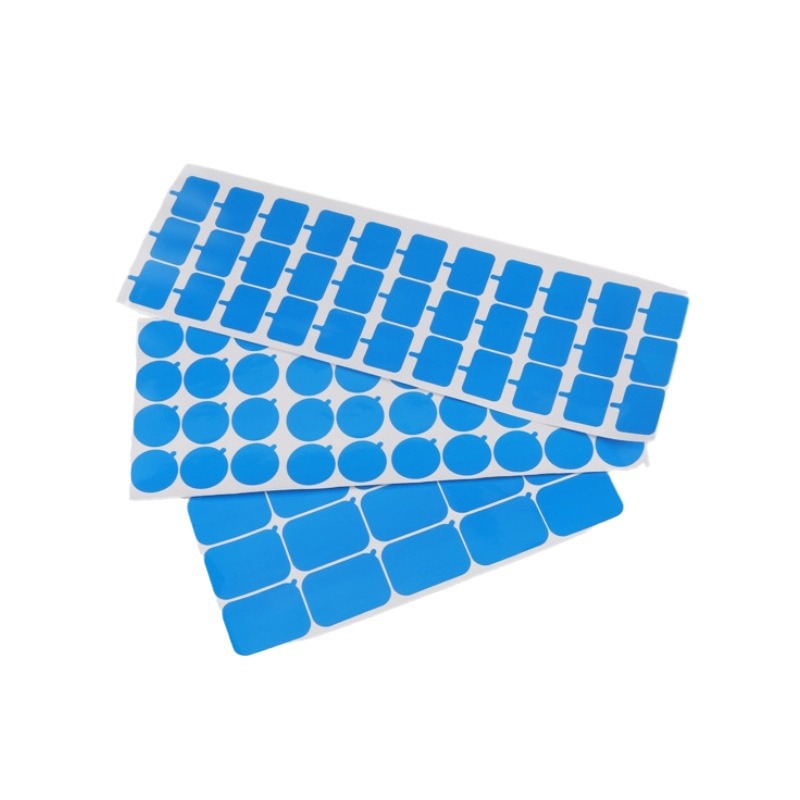

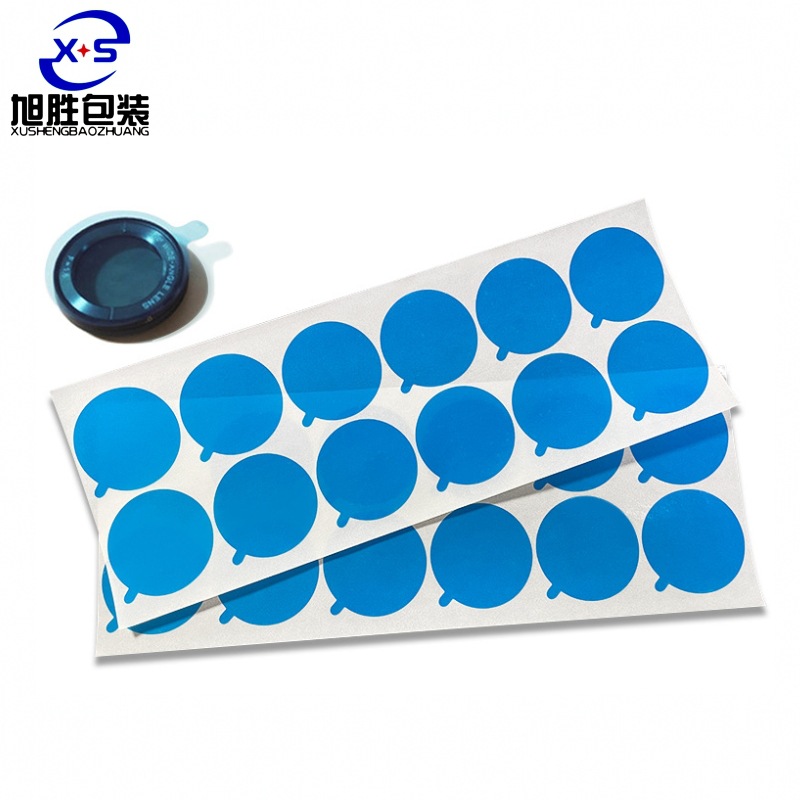

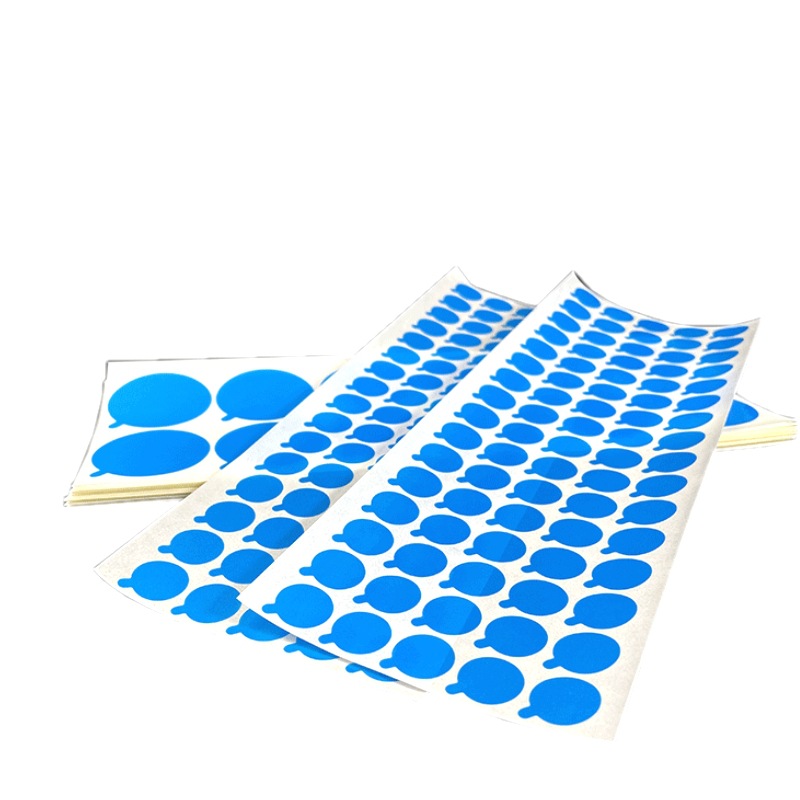

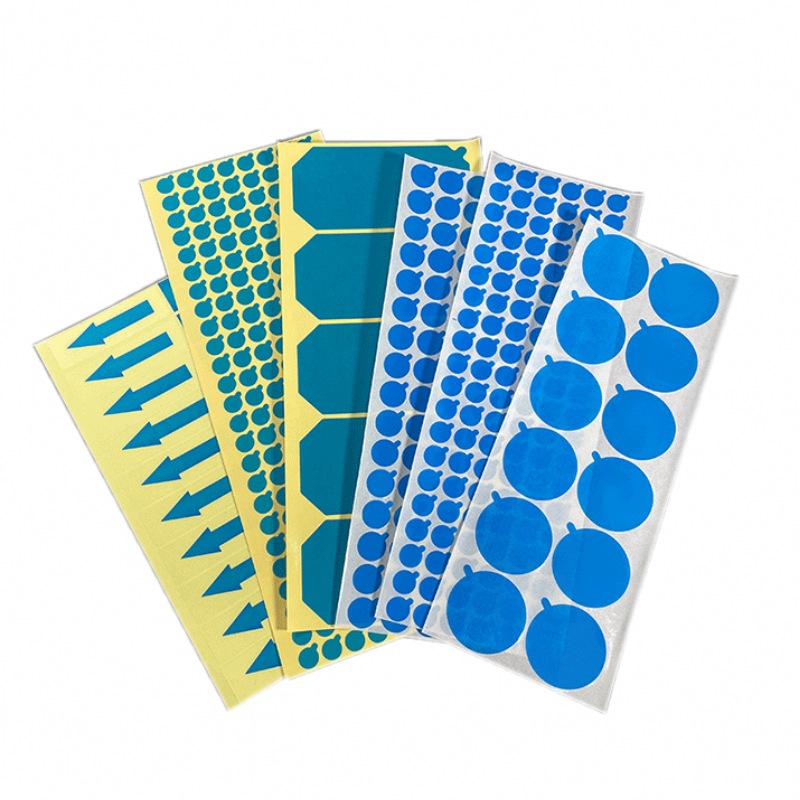

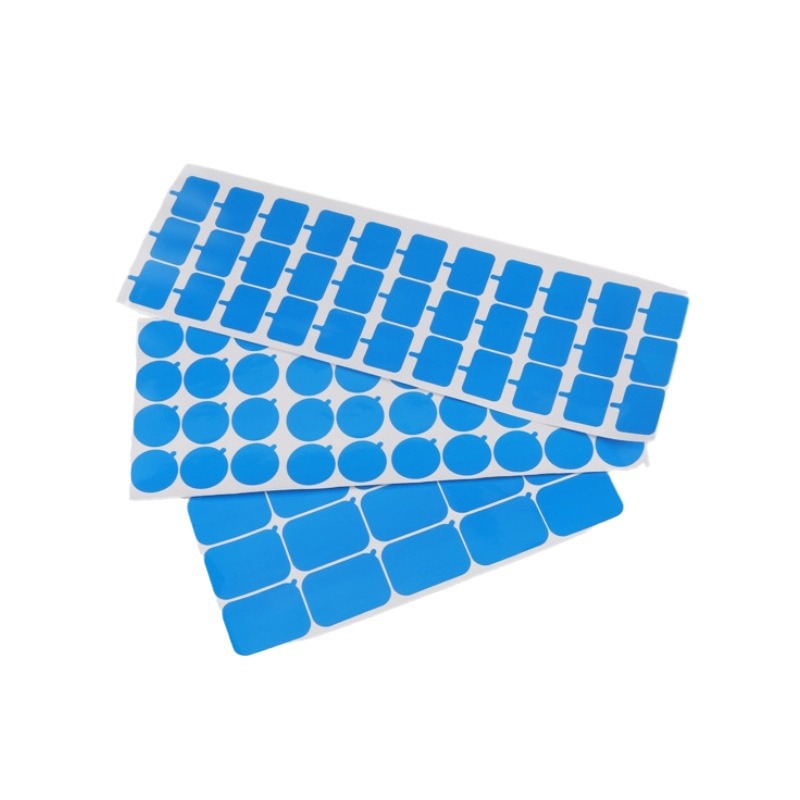

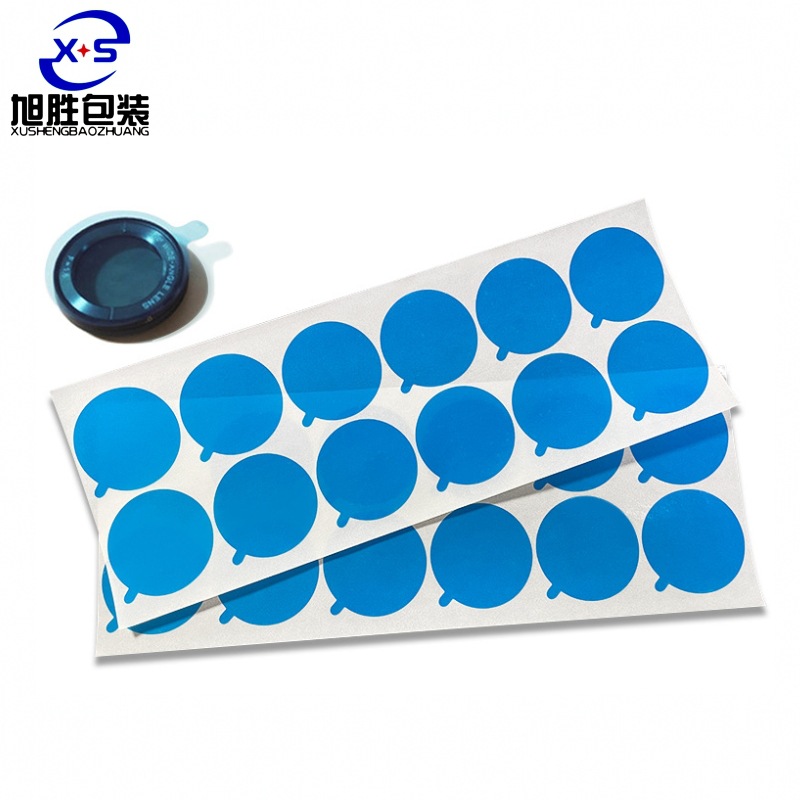

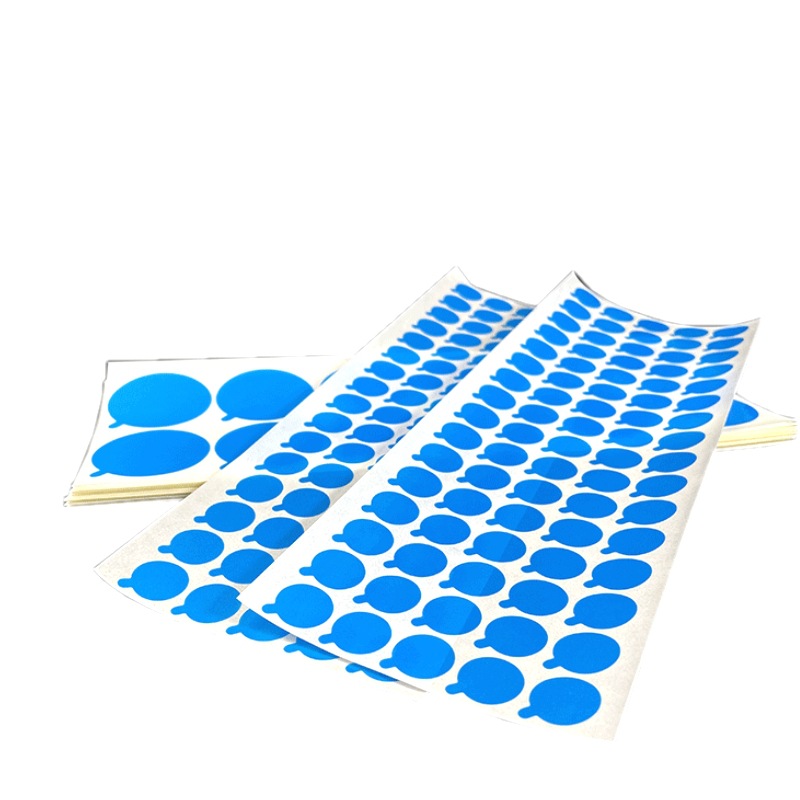

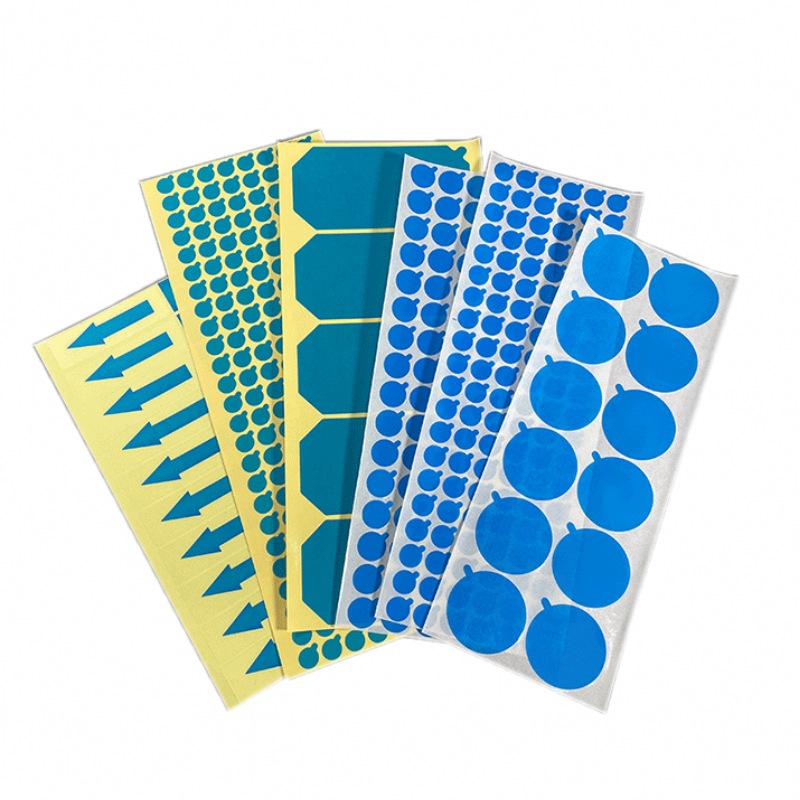

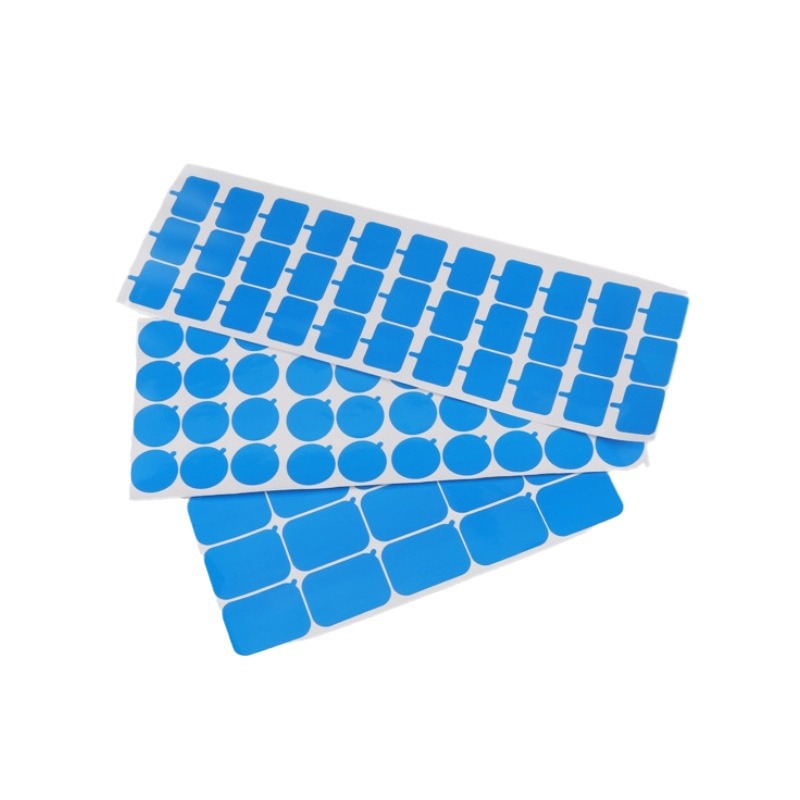

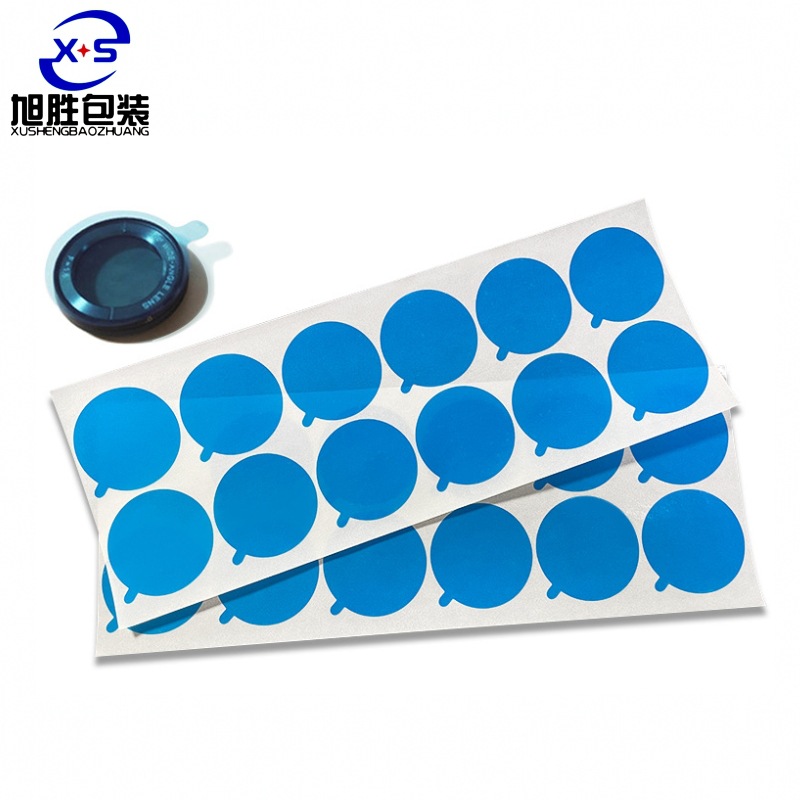

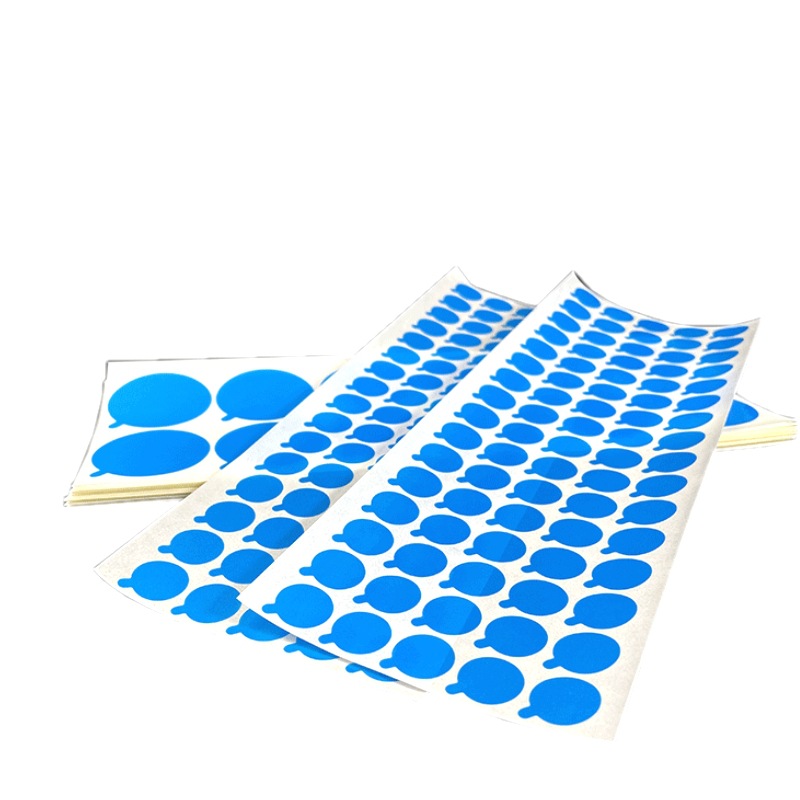

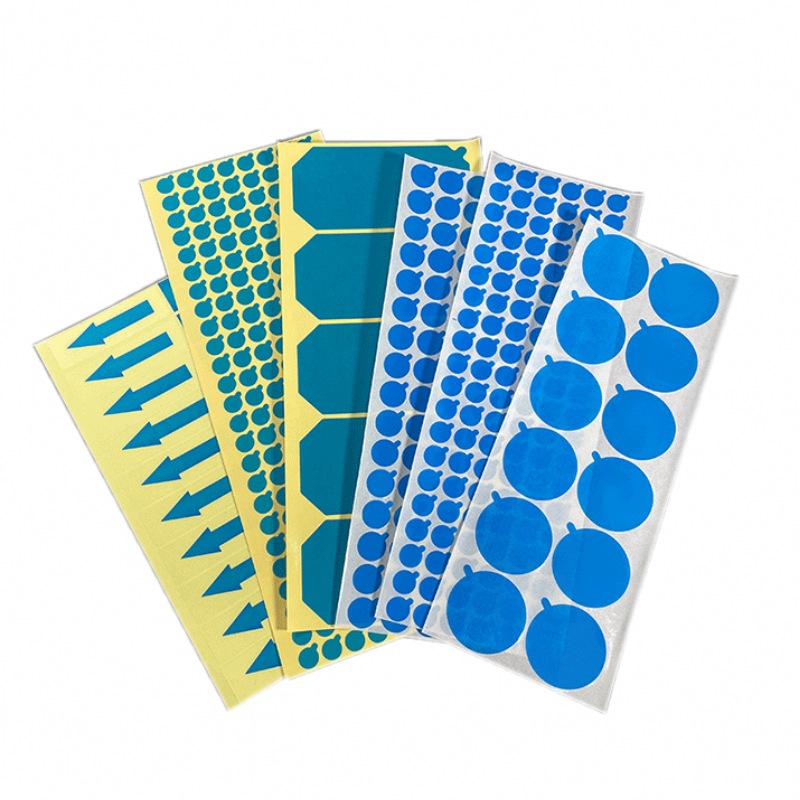

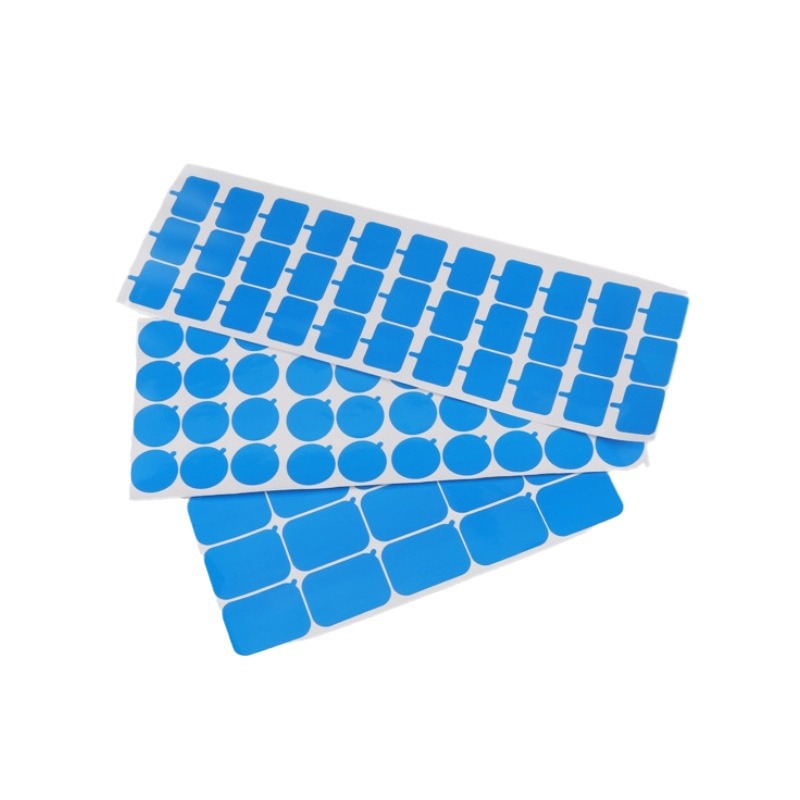

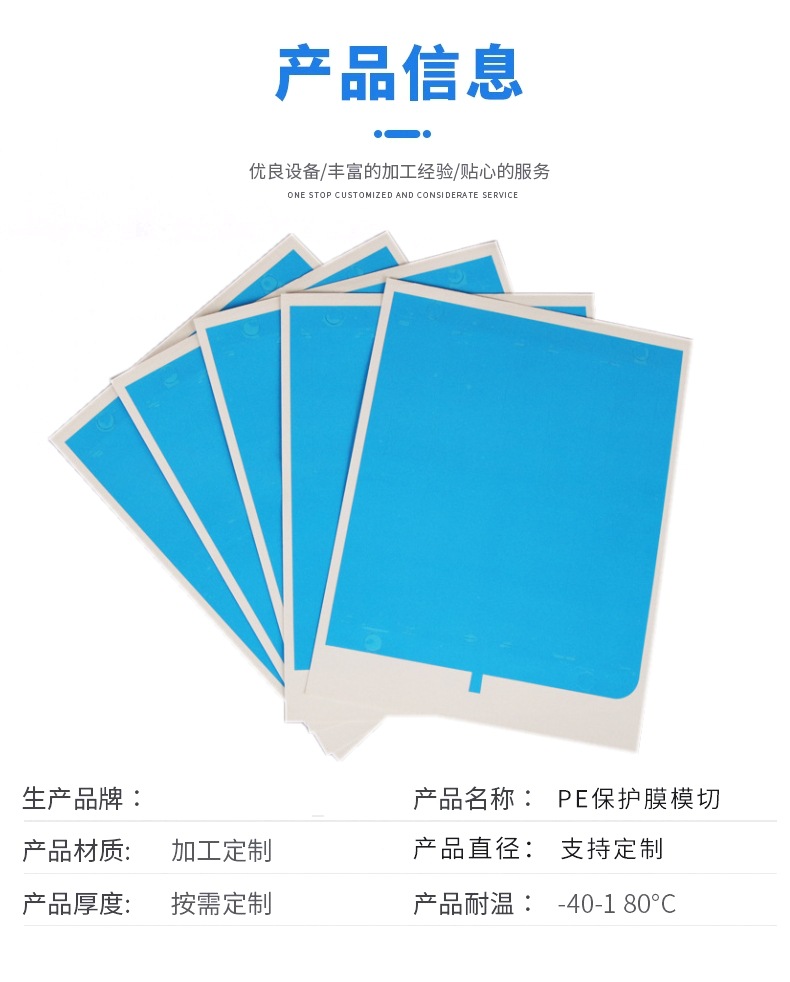

Dongguan Xusheng New Materials Co., Ltd. specializes in the production of pe protective film die-cutting, mirror protective film, lens special protective film, PE protective film, full name Polyethylene, is the simplest polymer organic compound structure, the world's most widely used polymer materials. PE protective film with special polyethylene (PE) plastic film as the base material, according to the density is divided into high density polyethylene protective film, medium density polyethylene and low density polyethylene. The biggest advantage of PE protective film is that the protected products are not polluted, corroded, scratched in the process of PE protective film production, processing, transportation, storage and use, and protect the original smooth and shiny surface, thereby improving the quality of products and market competitiveness

use

1. Hardware industry: computer case, galvanized sheet stamping, aluminum plate, stainless steel plate, titanium plate, plastic plate, glass plate, solar panels and so on.

2. Photoelectric industry: LCD LCD display, backlight plate, cold light film, film switch, mobile phone screen and so on.

3. Plastic industry: ABS, PP injection molding products, PVC sheets, acrylic sheets, instruments, plastic lenses, paint parts surface protection and so on.

4. Printing industry: PVC, PC board, aluminum plate, film and other printed nameplate surface protection and so on.

5. Wire and cable industry: protection of axle mounted copper wire, semi-finished products, finished products, rolled products, can effectively prevent dust pollution, anti-oxidation, anti-fouling effect.

6. The electronics industry, in the production, generally need to use the protection of finished products and semi-finished products, in the assembly line is not easy to scratch and damage!

7. Mobile phone digital industry, mobile phone film, also known as mobile phone beauty film, mobile phone protective film, is a cold surface film that can be used to install mobile phone body and screen.

Use requirement

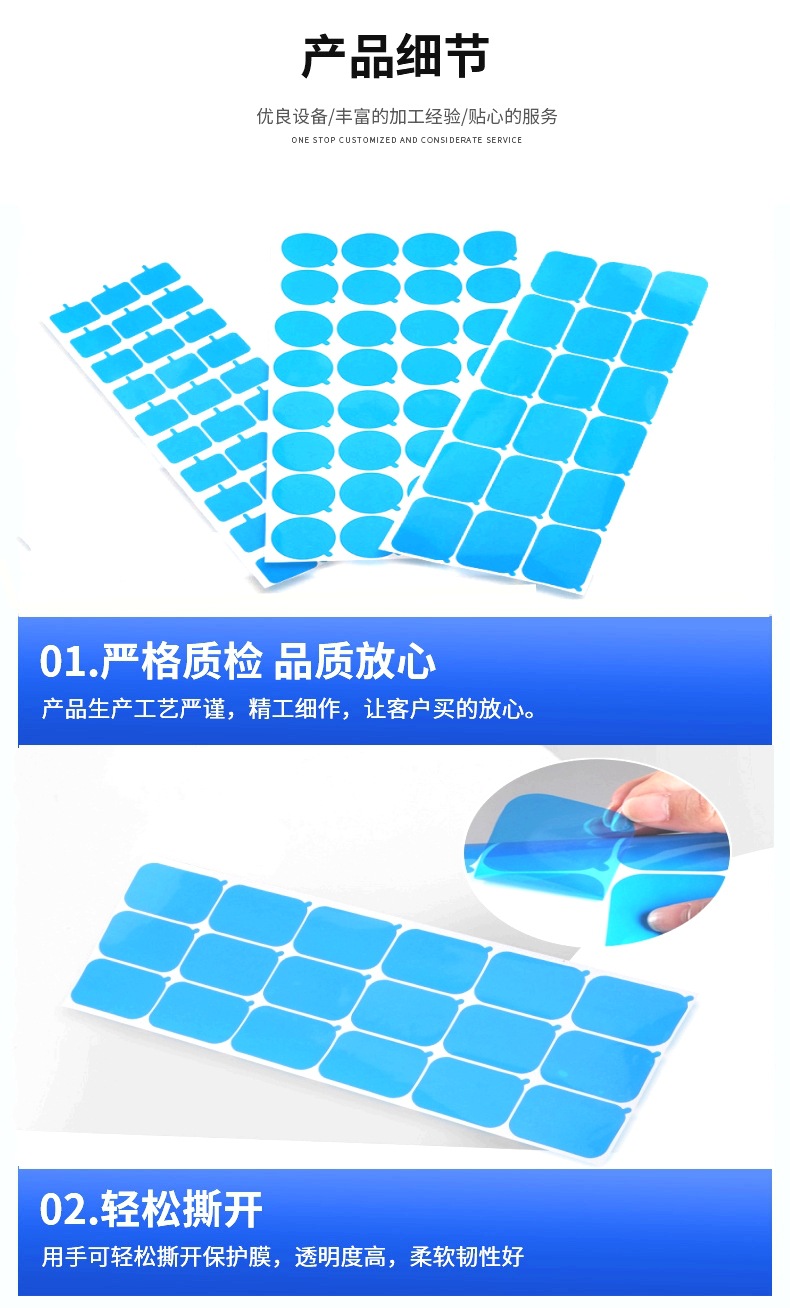

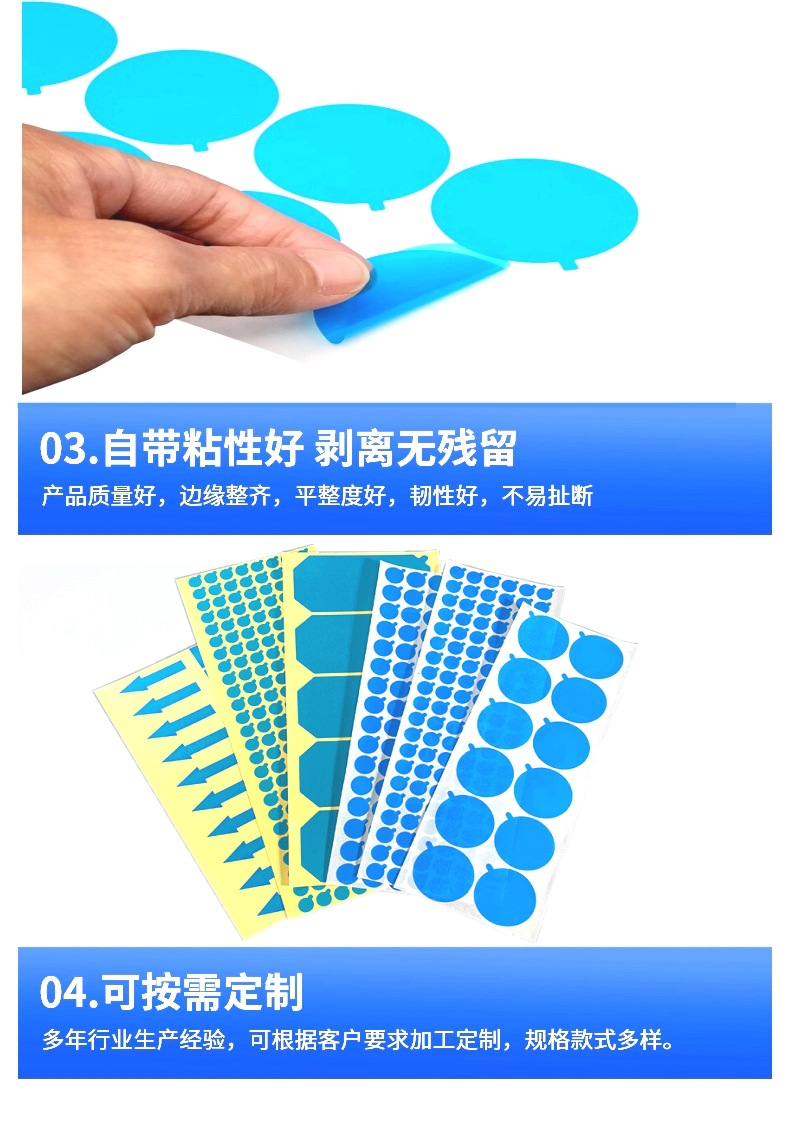

1, suitable viscosity: easy to stick and easy to tear;

2, stable stripping force: the change of the time is small, that is, the smaller the rise of stripping force, the better;

3, good weather resistance: under sun exposure conditions, the use period is as long as six months to one year;

4, long storage period: stored in the warehouse for more than one year, no change in quality;

5, no pollution, no corrosion: the adhesive is inert, will not chemically react with the surface of the adhesive material;

6, excellent mechanical properties: in line with user requirements of tensile strength, elastic modulus, elongation, etc.